CNC Machining

Our CNC Machining Services

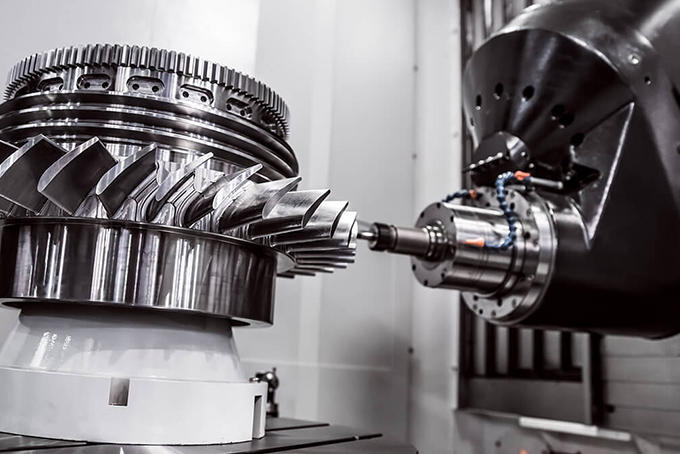

No matter if you need custom machined parts with complex geometries, or get end-use products in the shortest possible time, Kaida Copper is good enough to break through all of that and achieve your idea immediately. We operate over 150 sets of 3, 4, and 5-axis CNC machines, and offer 100+ different types of materials and surface finishes, guaranteeing quick turnaround and quality of one-off prototypes and production parts.

Our CNC milling process uses 3-axis & 5-axis CNC milling center to manufacture milled parts with tight tolerance up to ±0.0008″ (0.02 mm).

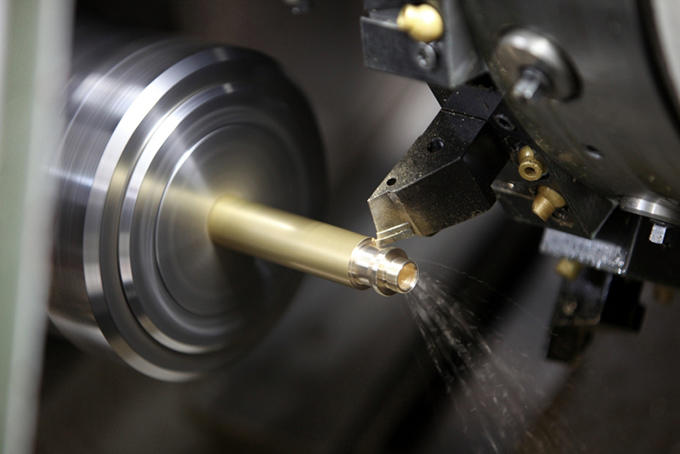

Our CNC turning process applies 50+ CNC lathes and CNC turning centers to create round or cylindrical turned parts with extreme precision.

Why Choose Kaida Custom CNC Machining Service

Online Instant Quote & DFM Analysis

No need to write a quote request email, get instant CNC quotes by simply uploading your design files. Our digital quoting platform analyzes your part geometry, and provides real-time & competitive pricing and comprehensive DFM feedback.

Consistent High Quality

We strictly implement a quality management system to ensure consistent, expected quality on the products. Full inspections also make sure you receive precision machined parts devoid of unwanted defects.

Fast Lead Time

Not only do we have a digital CNC machining services platform that provides faster ordering process, we also own domestic workshops and state-of-the-art machinery to accelerate the production of your prototypes or parts.

24/7 Engineering Support

No matter where you are, you can get our 24/7 engeering support all year around. Our experienced engineer can provide you with good appropriate solution to your part design, material selection, and surface finishing options and even lead time.

Quote in Seconds, Operate at Your Fingertips

As a tech-driven CNC machining company, we have developed AI powered quotation platform that simplifies your ordering and manufacturing process.

Instant Quotation

Get instant CNC quotes in a minute by simply uploading your design files. Our big data quoting engine calculates CNC machining quotes instantly and provides you with competitive prices.

DFM Feedback

Our platform built with an advanced machine learning algorithm can automatically identify part geometry that may be difficult to machine. Give you a comprehensive design-for-manufacturing analysis for your custom CNC parts within minutes.

All-in-One Order Management

Quickly check, search, and manage all your die casting orders in one place. What's even better is that you get visibility into all stages of the production process and every aspect of the manufacturing operation.

CNC Machining Tolerances

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

Materials for Custom CNC Machining Parts

A numebr of materials can be used in CNC machines, giving you various of options to complete rapid prototyping to production runs of custom complex parts. For your manufacturing needs, we provide instant quotatios of 100+ metals and plastics, and even you can compare prices for different machining materials.

- Copper Bar Processing

- Processing of Profiled Copper Products

Copper Bar Processing

Always-Observing Type No.: H59, HPb59-1, HPb59-3, H62, H65, H68, H70, H80, H90, C2600, C2680, C2700, C5210, C5191, C51000, QBe2.0, C1100, T2, etc.

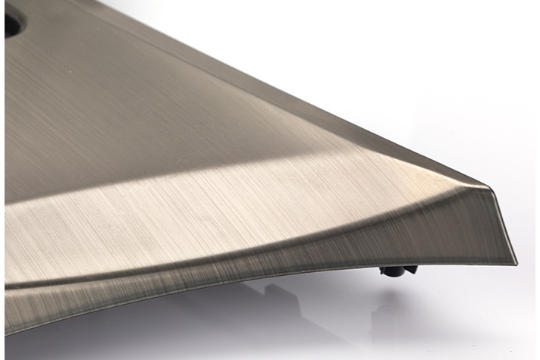

Processing of Profiled Copper Products

The multi axis CNC machine tool is used to process the blank with fine curved surface, reducing the processing time and improving the production efficiency

Surface Finishes for CNC Machining

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If don’t want as-machined parts, select a surface finishing for your custom parts. At Kaida, we offer several common surface finishes that help improve functionality and aesthetics.

| Name | Description | Materials | Color | Texture |

| Name | Description | Materials | Color | Texture | ||

|

|

Anodizing | Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface. Widely used in mechanical parts, aircraft, and automobile parts, precision instruments, etc. | Aluminum | Clear, black, grey, red, blue, gold. | Smooth, matte finish. | |

|

Bead Blasting | Bead blasting results in parts with a smooth surface with a matte texture. Used mainly for visual applications and can be followed by other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | n/a | Matte | |

|

Powder Coating | Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. | Aluminum, Stainless Steel, Steel | Black, any RAL code or Pantone number | Gloss or semi-gloss | |

|

Electroplating | Electroplating can be functional, decorative or corrosion-related. Many industries use the process, including the automotive sector, in which chrome-plating of steel automobile parts is common. | Aluminum, steel, stainless steel | n/a | Smooth, glossy finish | |

|

|

Polishing |

Polishing is the process of creating a smooth and shiny surface, either through physical rubbing of the part or by chemical interference. The process produces a surface with significant specular reflection, but in some materials is able to reduce diffuse reflection. |

Aluminum, Brass, Stainless Steel, Steel |

n/a |

Glossy |

|

|

Brushing | Brushing is a surface treatment process in which abrasive belts are used to draw traces on the surface of a material, usually for aesthetic purposes. |

ABS, Aluminum, Brass, Stainless Steel, Steel |

n/a | satin |

Order CNC Machined Parts Online

We provide CNC machining services of any complexity for the production of both small and large series of parts. Our online Instant Quoting Engine gives you a CNC machining quote within seconds. Then, we make your machined metal or plastic parts and get them to your door in up to 10 days. We inspect the parts and guarantee their quality. Requesting a quotation for CNC machining is easy: just upload your files with drawings, 3D-models or sketches in any popular format.

-

CNC Turning

2-axis CNC lathes, Swiss-type lathes

-

CNC Milling

3-, 4- and 5-axis CNC machines

-

CNC Drilling

Upright, bench, radial drill presses

Gallery of CNC Machined Parts

Check out our extensive gallery that shows precision machined prototypes and parts from our valued customers.

Our Die Casting Serves Nearly All Industries

Kaida Copper works with leading manufacturers from different industries to support growing demands and streamline their supply chain. The digitalization of our custom die casting services helps more and more manufacturers bring their idea to products.

Automotive Industries

Aerospace

Thermal Converter

Household Items

Contcat Us

Address: No.9 Xuancheng Road, Yuhuan Economic Development Zone, Yuhuan City, Zhejiang, China

Tel: +86-576-87120903/87120901

Mobile&Wechat: +86-576-81718209

E-mail: [email protected]

EN

EN

西班牙语

西班牙语