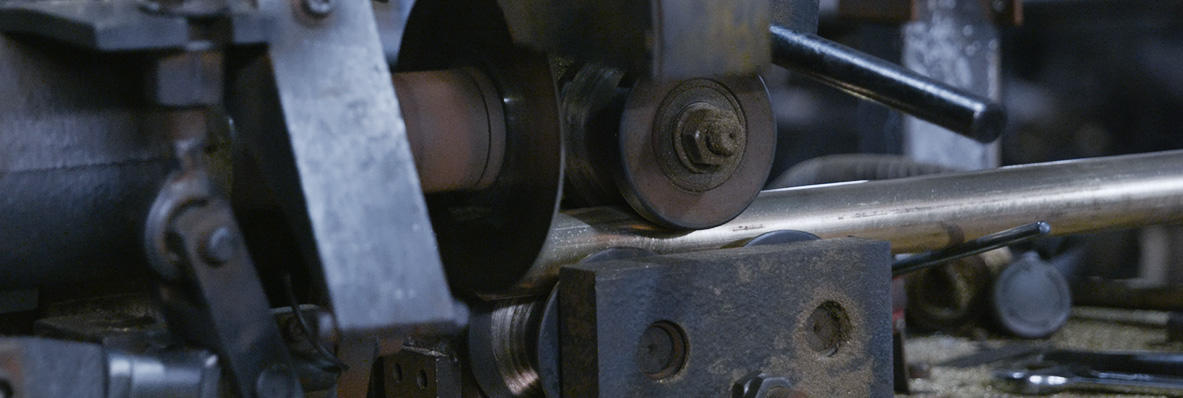

Custom Forged Parts

Almost OEMs lack the facilities to produce all of the parts they need, and this can be particularly true for parts that are good fabricated by forging. Forging brings with it a number of advantages, the primary one being that metal can be precisely shaped, and its grain flow controlled, to produce a part that is ductile, tough, and highly resistant to fatigue.

Forging is also a method of choice for parts that are too large to be fabricated by other manufacturing methods.

Since the forging process can readily be combined with machining, shape, and tolerance requirements are generally limited only by the creative skills of the designers and the manufacturing workforce.

For certain types of parts, forging can be an extremely cost-effective fabricating method, since less initial material is required to produce a given part, and there is a minimal waste as compared to parts fabrication practices involving subtraction by cutting. Machining costs tend to be reduced as well, and parts rejection rates approach zero, as compared to welded and joint parts that have less structural integrity. Forged parts are also stronger than castings.

Forging is an excellent method for producing large, one-of-a-kind, or limited-production parts.

Brass Castings and Forgings

Casting and Forgings – Make stronger, more efficient, and better-optimized parts by forging or casting before machining.

Casting and Forgings – Make stronger, more efficient, and better-optimized parts by forging or casting before machining.

Custom Forged Brass

|

Forged brass is used in a large number of different industries where forged brass can’t deliver a comparable level of high strength and extended wear. These are generally industries that make use of components that need to be able to withstand heavy daily use, such as military, marine, naval, chemical, shipping, petrochemical, food processing, power generation, construction, automotive, and general engineering. |

Forgings Brass

|

Forged brass combines the strength of copper with exceptional heat and corrosion resistance. Thanks to the stability and high strength of the material, copper parts demonstrate outstanding performance within high-stress and heavy-wear environments. |

Magnesium Forgings

|

Magnesium alloys are used around the world thanks to their lightweight and high-strength properties. They are the material of choice for the fabrication of various automotive, aerospace, industrial, and materials-handling applications. |

Forging Process Flow

EN

EN

西班牙语

西班牙语