Advanced PVD Surface Treatment Center

Creating Durable and Lustrous Finishes for Premium Brass Products

A New Era in Brass Surface Treatment

KAIDA BRASS has launched its advanced PVD (Physical Vapor Deposition) facility

We provide consistent quality and customized solutions for brass products:

Beyond Tradition

Addressing limitations of electroplating in wear resistance and environmental impact

Color Innovation

Achieving metallic finishes beyond conventional techniques

Performance Enhancement

Combining artistic beauty with industrial strength

"Not just equipment installation, but a technological revolution tailored for brass products"

Advanced Equipment

Our PVD systems ensure quality surface treatment

CICEL PVD

German-engineered multi-arc magnetron system optimized for brass alloys

- Max processing size: Φ1800mm × H2200mm

- Sputtering targets: 27 units

- Temperature control: ±5℃

PlasmaClean

Ensures substrate cleanliness for coating adhesion

- Dual RF plasma sources

- Automated cleaning programs

- Multiple gas cleaning options

- 40% increased efficiency

QualityLab Pro

Comprehensive testing equipment for quality assurance

- Coating thickness measurement

- Adhesion testing

- Salt spray test chamber

- Color difference analyzer

Equipment Commissioning Progress

We are optimizing our systems to ensure performance

New Facility · Professional Standards

We've established standards for professional PVD treatment

Brass-Specific Process Development

- Premium equipment: CICEL multi-arc magnetron system

- Rigorous testing: 200+ brass substrate trials

- Class 10,000 cleanroom environment

- German engineering team support

Quality Commitments

- Coating adhesion: Class 5B (ISO 2409)

- Corrosion resistance: >72h neutral salt spray (ASTM B117)

- Environmental compliance: Zero cyanide wastewater · RoHS/REACH

- Heat resistance: 400℃ without discoloration

Current Capabilities

We offer mature PVD surface treatment technologies and processes

Production-Ready Technologies

Classic Finishes:

Performance:

- Hardness: HV 800-2200 (adjustable)

- Heat resistance: 400℃ without discoloration

- Coating thickness precision: ±0.2μm

- Electrical conductivity retention: >90%

2025 Technology Roadmap

- Enhanced-wear-resistant nanocomposite coatings (Q3 launch)

Hardness increased to HV 3000+, wear resistance improved 3x - PVD + laser etching texture process (R&D)

Micron-level precision textures for enhanced design - Antibacterial brass treatment (Patent pending)

99.9% antibacterial rate for medical & food applications - Smart temperature control system (Q4 launch)

±5℃ precision for sensitive components

Technology Development Milestones

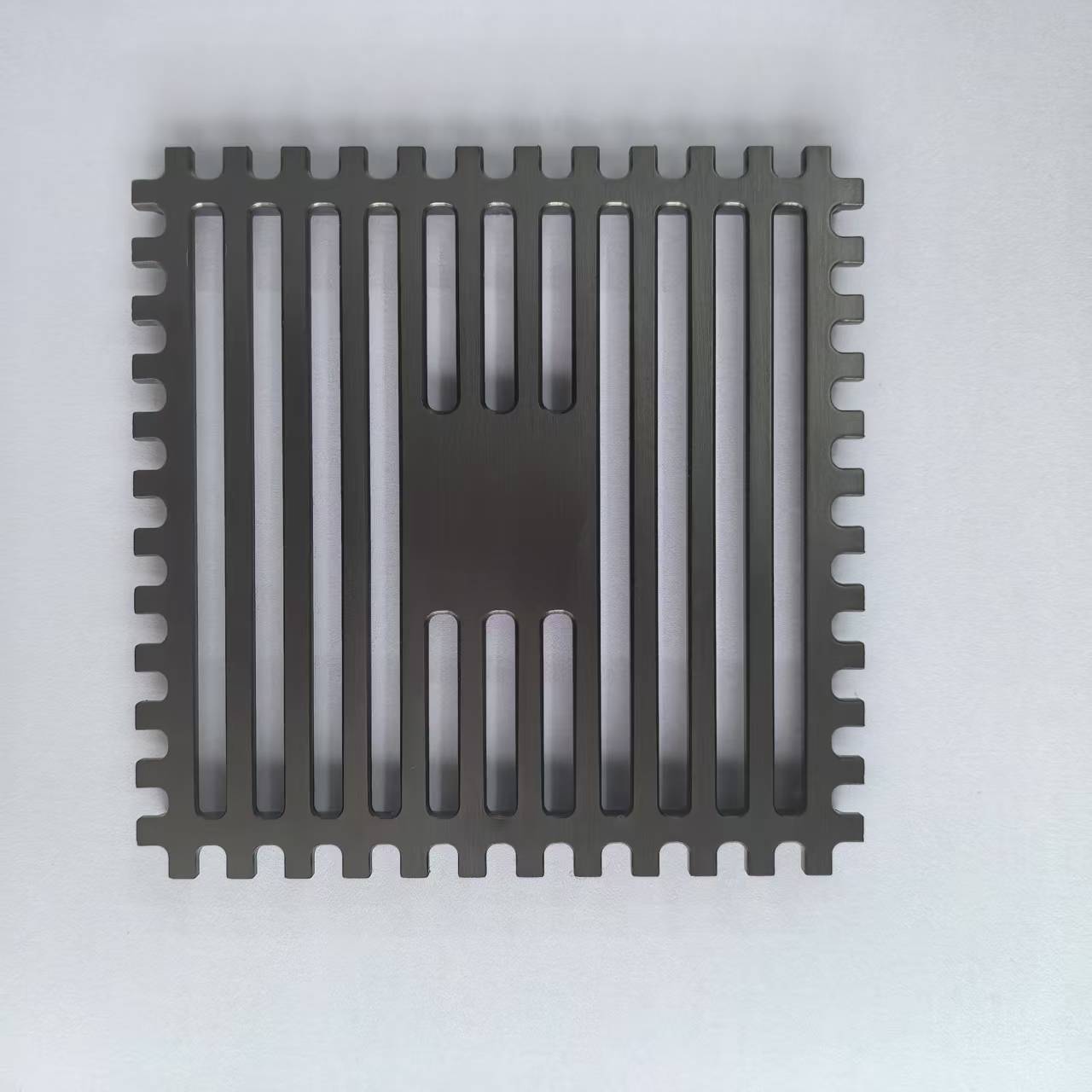

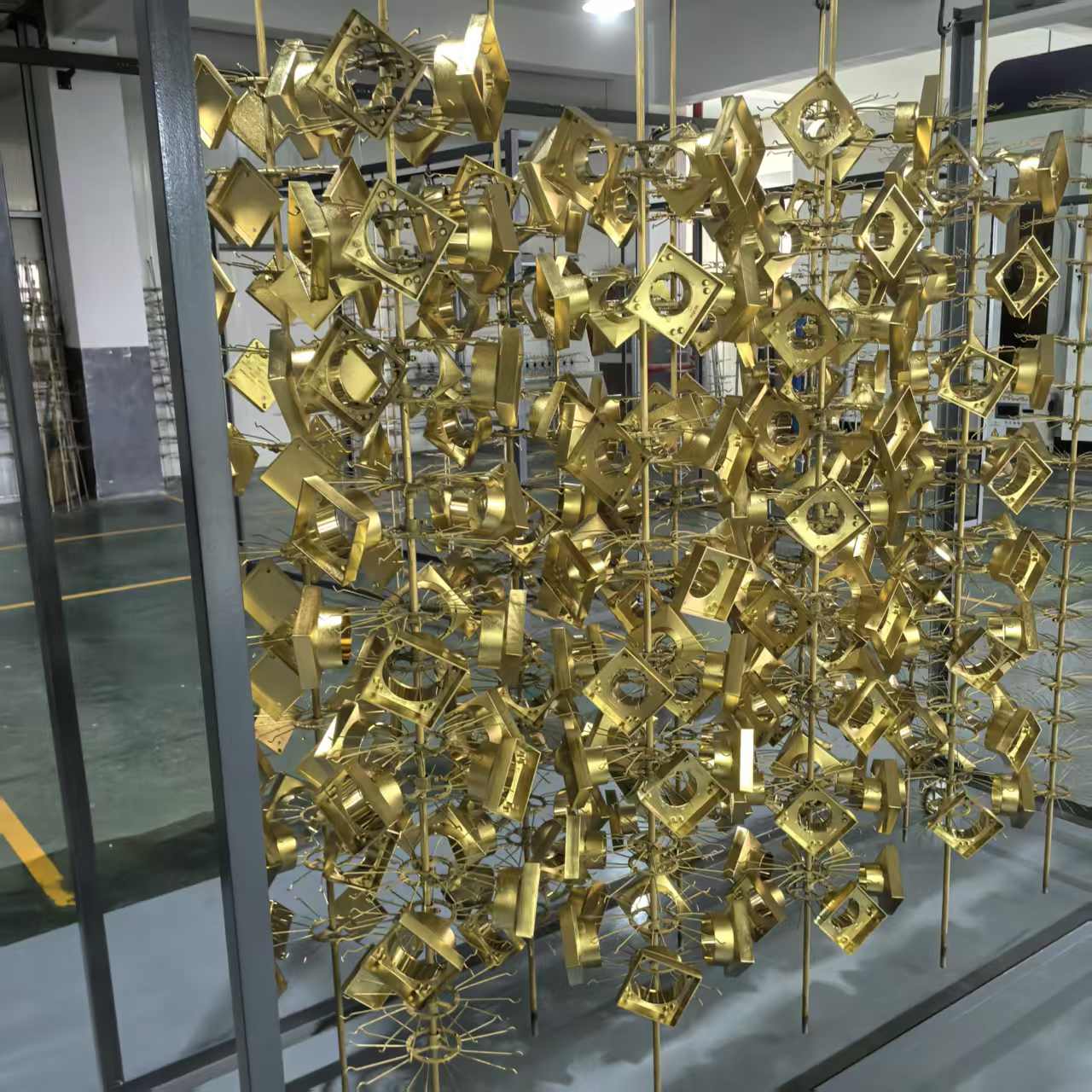

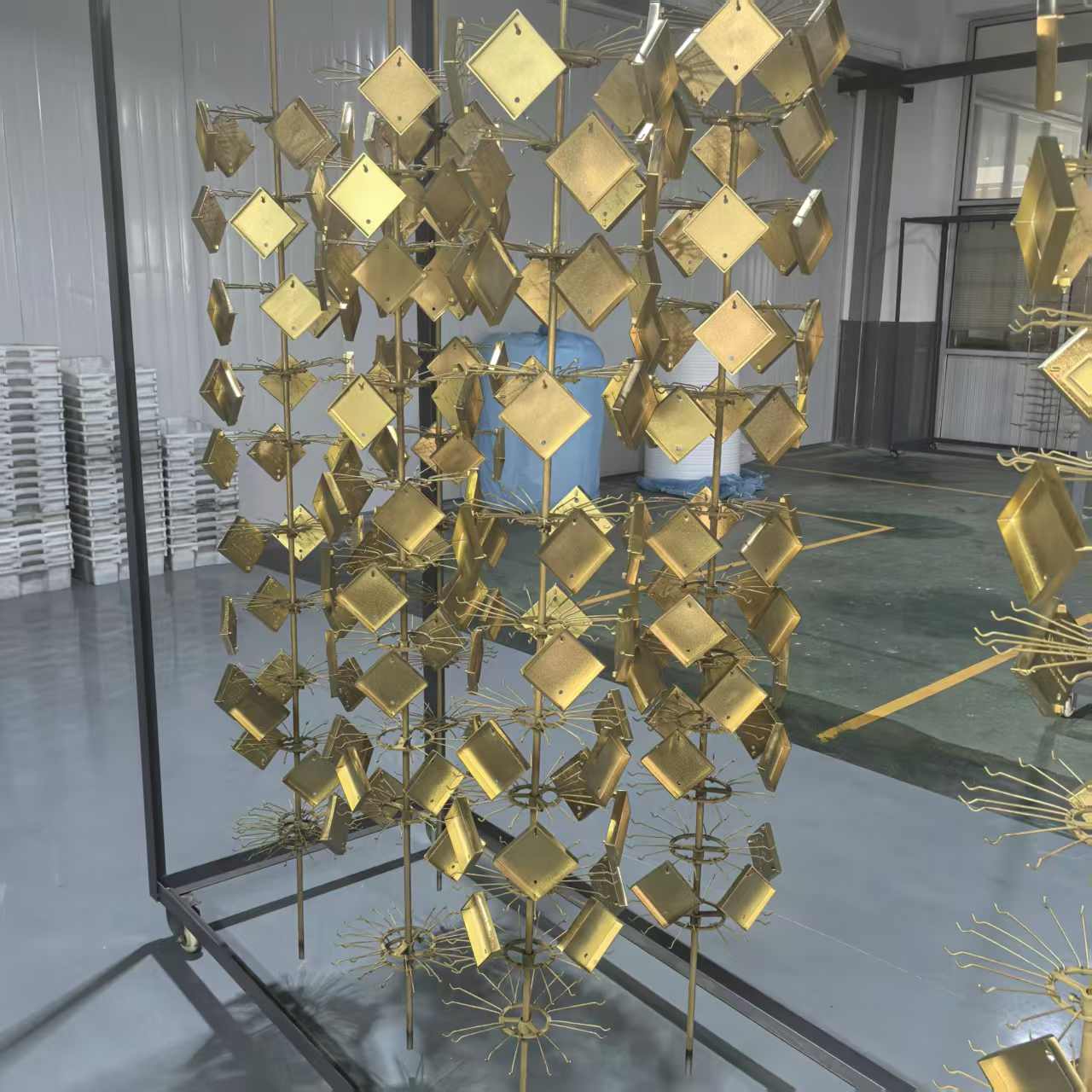

Our PVD Treatment Gallery

Explore the finishes of our advanced PVD technology

Key Application Areas

We specialize in PVD treatment for brass products in these sectors

| Application | Typical Products | Core Value |

|---|---|---|

| Architectural | Door handles/Facade elements/Bathroom fixtures | Weather resistance/Fingerprint-proof/10-year color guarantee |

| Premium Homeware | Cookware/Lighting/Art decor | Food-grade safety/Easy cleaning/Long-lasting beauty |

| Industrial Components | Heat sinks/Conductive parts/Bearings | Enhanced wear resistance/Reduced friction/Heat tolerance |

| Electronics | Audio panels/Connectors/Heat spreaders | High conductivity/EMI shielding/Corrosion resistance |

| Gifts & Awards | Trophies/Commemorative coins/Premium pens | Luxurious finish/Permanent color/Unique designs |

Technology Partnership Program

Join us in exploring new possibilities for brass surface treatment

Joint R&D

Co-develop surface solutions for specific applications

Sample Testing

Free sample testing with technical analysis report

Process Optimization

Tailored treatment processes for your products

Strategic Partnership

Long-term collaboration for market development

Ready to Enhance Your Brass Products?

Contact us today to discuss how our PVD surface treatment can add value to your products

Request Consultation

EN

EN

西班牙语

西班牙语