What are the advantages and disadvantages of Brass Lamp Parts compared to lamp fittings made of other materials?

Brass Lamp Parts have the following advantages and disadvantages compared to lamp fittings made of other materials:

advantage:

1. Strong corrosion resistance: Brass Lamp Parts are not easy to corrode after long-term use, and can maintain good appearance and performance.

2. Good heat resistance: Brass Lamp Parts has good heat resistance and is suitable for the manufacture of lamps in high temperature environments.

3. High Strength: The strength of Brass Lamp Parts is higher than many other materials, which can ensure the stability and safety of the lamp.

4. Ease of Processing and Manufacture: Brass Lamp Parts can be manufactured into lamp fittings of various shapes and sizes through a variety of processing methods.

5. Good plasticity: Brass Lamp Parts can change shape and size through heating and cooling, suitable for manufacturing lamps of different shapes.

shortcoming:

1. Higher cost: Brass Lamp Parts are more costly and require higher manufacturing costs compared to some plastics, alloys, etc.

2. Heavy Weight: Brass Lamp Parts are heavy and not suitable for use where a lightweight light fixture is required.

3. Surface treatment of metal materials: In order to maintain the smoothness and brightness of the surface, Brass Lamp Parts need to be cleaned and polished regularly, otherwise it will oxidize and lose brightness.

What is the importance of Brass Lamp Parts in lamp design and manufacture?

Brass Lamp Parts play a very important role in the design and manufacture of lamps, which can affect the appearance, performance and service life of the lamp.

First of all, Brass Lamp Parts can be used as one of the main materials of lamps, providing excellent physical and chemical properties such as strength, corrosion resistance, and heat resistance, ensuring the stability and safety of lamps. For example, lamp holders, lanterns, connectors and other parts of lamps can be made of Brass Lamp Parts material to provide better performance and appearance.

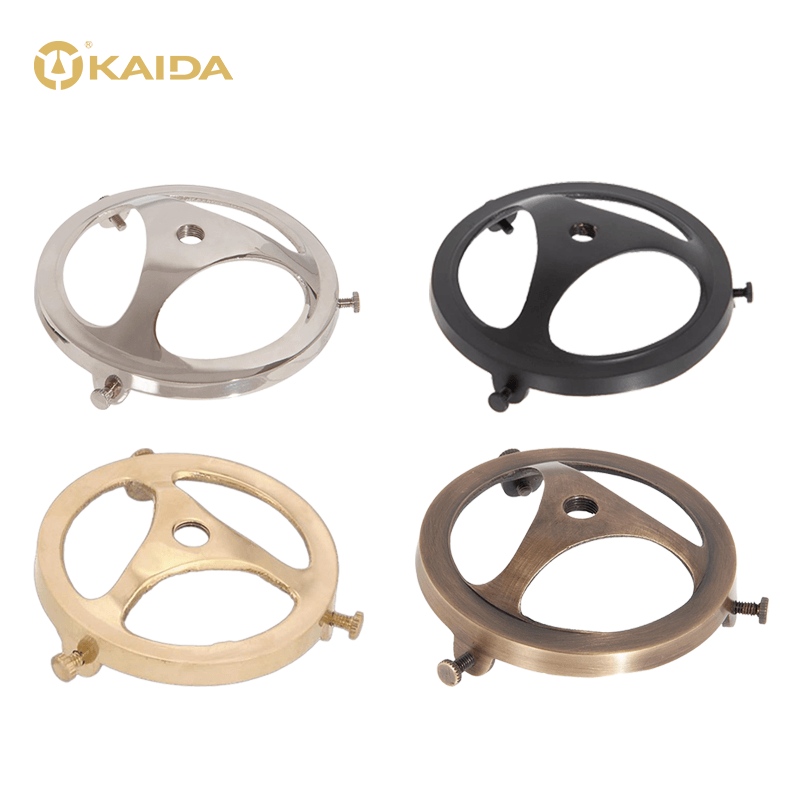

Secondly, Brass Lamp Parts can provide a variety of design and manufacturing methods, which can be customized according to different design requirements and lamp types. For example, lighting accessories of different shapes, sizes and styles can be manufactured through processing, casting, sheet metal, etc. to meet the needs of different consumers in the market.

In addition, Brass Lamp Parts can also play an important role in the assembly and repair process of lamps, which can be easily disassembled, replaced and repaired to extend the service life of lamps.

What is the difference between brass lighting parts and copper lamp parts?

Brass lighting parts and copper lamp parts are both commonly used in the manufacturing of lighting fixtures, but they differ in terms of their composition and characteristics. Brass is an alloy of copper and zinc, while copper lamp parts are made purely of copper.

Brass lighting parts offer several advantages. Firstly, brass is known for its excellent corrosion resistance, making it ideal for outdoor or humid environments. It is also highly durable and can withstand prolonged use without degradation. Additionally, brass has good thermal conductivity, allowing for efficient heat dissipation in lighting fixtures. Furthermore, brass can be easily machined and formed into intricate designs, offering flexibility in the creation of decorative lighting pieces.

On the other hand, copper lamp parts have their own unique properties. Copper is a highly conductive material, making it suitable for applications where efficient electrical conductivity is crucial. It is often chosen for its aesthetic appeal, as copper develops a distinct patina over time, lending a rustic and vintage look to the lamp. Copper lamp parts are also valued for their antimicrobial properties, making them hygienic choices for certain settings.

EN

EN

西班牙语

西班牙语